Canopy Management – looking back, looking ahead

As first seen in the Orchardist, August 2020

Jack Hughes, Horticultural Consultant, Fruition , Hawke’s Bay

This article reflects on changing pruning and canopy management styles in apples and considers some of the drivers of change. We then discuss new scanning technology that is improving our ability to measure and act on crop and canopy variability within our orchards.

A fleeting history

Apple pruning styles keep evolving. From around 50 years ago, the industry transitioned from multi-leader trees planted at 400-500 trees per hectare to MacKensie single leaders at densities of 500-667. Back then, the pruning style was to ‘cut back to fruit’- that is removing 1 year olds to leave the older wood with fruiting spurs. Unlike today, this type of heading back was considered ok even if wood was upright. Of course, this style gave undesirable responses resulting in more upright growth and trees became ‘stroppy’ in their tops and shaded in the bottoms.

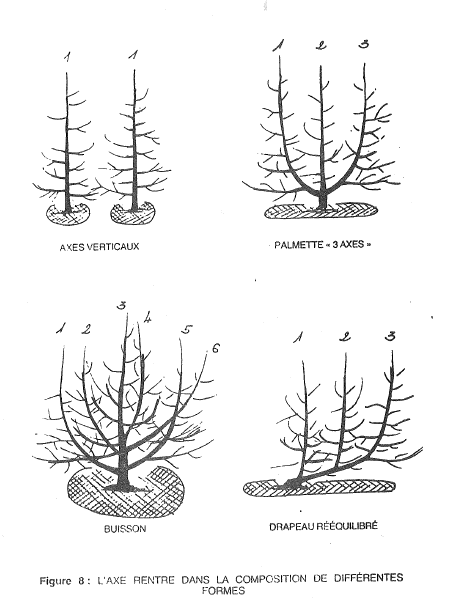

Then Jean-Marie Lespinasse introduced the axis system and the concepts of renewal pruning (Figure 1).

Figure 1. Different axis tree forms. From Apple Tree Management. JM Lespinasse (1980)

We ‘unlearned’ heading back in favour of letting branches develop naturally and produce lots of fruiting spurs. Fruiting branches would typically droop below the horizontal and eventually accumulate too many, weak spurs. In the renewal style, these branches would be shortened back to horizontal wood to remove surplus fruiting wood. Branches could also be removed completely if they were too big or crowded. The introduction of structural pruning and removal of big branches in tree tops received something of a ‘shock – horror’ reception at first. However, this new approach was transformational and raised the bar on productivity. At that time, most trees were growing on moderately vigorous rootstocks so the fruitfulness/vigour balance of trees was often pushed towards too much vigour.

We ‘unlearned’ heading back in favour of letting branches develop naturally and produce lots of fruiting spurs. Fruiting branches would typically droop below the horizontal and eventually accumulate too many, weak spurs. In the renewal style, these branches would be shortened back to horizontal wood to remove surplus fruiting wood. Branches could also be removed completely if they were too big or crowded. The introduction of structural pruning and removal of big branches in tree tops received something of a ‘shock – horror’ reception at first. However, this new approach was transformational and raised the bar on productivity. At that time, most trees were growing on moderately vigorous rootstocks so the fruitfulness/vigour balance of trees was often pushed towards too much vigour.

The introduction of more dwarfing rootstocks helped with addressing the excess vigour problem along with the next evolution in pruning/training style. Branches were trained into pendant orientations and allowed to grow long. Vegetative uprights were still removed and there was more attention to the number of spurs and their quality. Weak and underneath spurs are targeted for removal. Matching bud counts to target yields was considered and applied to varying levels of precision depending on people’s preferences and safety margins.

The approach with detailed pruning cuts is the next item on our whirlwind history. Previously cuts had to be flush and leaving ‘coat-hangers’ was a big no-no. Now ‘stub’ or ‘bevel’ cuts which leave buds for the re-growth of replacement shoots is tolerated or even promoted (Figure 2). A 360° change.

Previously, pruning has been considered a one-time, dormant season job. These days the value of summer pruning to improve the canopy light environment and regulate tree vigour is more accepted. Summertime stub cuts achieve this with minimal regrowth along with the frequent development of fruitful buds behind the cuts. So a new type and timing of cuts is achieving a beneficial outcome with minimal adverse side effects. These changes have required some ‘unlearning’ of previously accepted ideas.

Figure 2. Regrowth from ‘stub’ cuts

More canopy means more crop , right?

The move to narrow, planar canopies whether they be V’s, twin stems, 2D’s, FOP’s or their emerging variants is fueled by the productivity gains on offer. We used to equate more canopy with more yield but have now learned that this ain’t necessarily so. The introduction of cab tractors required the removal branches that protrude into the row alley to give safe and damage free access. Despite fears, this narrowing up of the ‘row end profile’ hasn’t usually hurt yield. Often quite the opposite. Tony Waites of Mr Apple, has observed a pattern amongst his blocks where the greater the visibility down the row (i.e. the further you can see), the greater the yield.

Mechanically trimmed canopies are also now beginning to demonstrate positive ‘cost/benefit’ track record (Figure 3).

The trimmer sets a uniform canopy profile and the mid-summer timing minimises regrowth. A useful proportion of buds behind the cuts will become floral to add to the benefit.

Figure 3. A trimmed canopy at Johnny Appleseed

Platform friendly canopies

Robot ready canopies is a new phrase that nicely captures the need to modify canopy design to accommodate the prospect of robotic harvesting. We’re yet to see robots match the economic performance of skilled picking gangs but many think it will happen. The potential disruption to labour availability caused by the Covid pandemic is, however, forcing a rethink. ‘Platform friendly’ canopies will be highly desirable if we are forced to make more use of ‘less able bodies’ for pruning, branch training, fruit thinning and picking in our orchards. A platform compatible canopy has to be uniform in profile and thin in depth to ensure easy access for all tree work.

Canopy geometry

The planar canopies have much smaller canopy volumes than their 3 dimensional (3D) predecessors, often by less than half. Canopy density is a qualitative canopy description that until now has been difficult to measure. As canopies get denser, fruit colouration and dry matter decreases. Over time, spur strength and ability to set fruit diminishes. So canopy density does matter.

So, an objective, accurate and repeatable measure of canopy density is required to enable comparison of blocks and, equally importantly, to measure the variation within blocks. New ‘tech’ has come of age to do this. Scanning with LiDAR provides an accurate and objective way to measure canopy geometry. [The LiDAR instrument fires rapid pulses of laser light at the target. A sensor on the instrument measures the amount of time it takes for each pulse to bounce back. Differences in return time are used to calculate distance and location and generate 3D images].

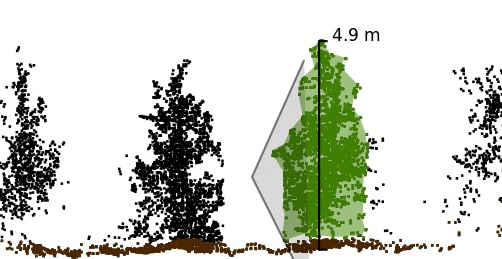

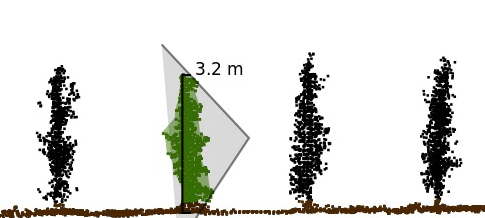

The LiDAR images in Figures 4 and 5 show canopy height (the height bar), canopy volume (the green shaded area). Canopy density is determined by whether the millions of laser beams either pass through the canopy or strike the tree. Density is simply expressed as the percentage of ‘hits’ and vary from 40% in open textured canopies to 70% in denser ones.

Figure 4. Canopy geometry in a modern 3D canopy Figure 5. Canopy geometry in a 2D canopy

Scanning for crop load and estimation is done after hand thinning is finished. This mid-season timing is also ideal for canopy measurement because shoot growth has mostly finished by then. So its two birds with one stone. There is still more work to do to calibrate the data – i.e. to understand how ‘open’ a canopy needs to be to give uniformly high quality fruit, and where the ‘shady’ tipping point that results in too much inferior, low dry matter fruit starts.

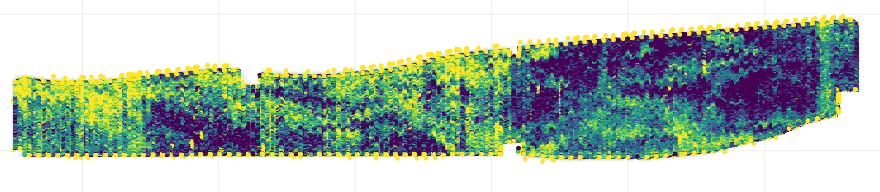

Figure 6 shows a heat map of canopy volume of a 7ha block of 3rd leaf apples. The soil types in this block vary considerably and this is already showing through quite strongly in the way the trees are growing. The darker blue areas shown higher vigour, larger trees and the yellow areas show where the trees are struggling. The trees are already uneven and without management intervention, this will likely get worse over time and affect the block’s performance.

Figure 6 LiDAR scan of canopy volume in a 7ha block of apples

You’d be right to think that this is only a pretty picture unless it can be used to do something useful. This is where software tools from precision agriculture come into play. So called prescription maps create data files that tells GPS enabled equipment where to, say, spread fertiliser or spray chosen products.

There is flexibility in deciding how many different zones are required. For example, we might select 3 zones (low, moderate and high vigour) and apply supplemental fertiliser to just the low vigour areas and shoot growth inhibition sprays (prohexadione calcium) to just the high vigour areas. Other more permanent changes could be considered like adding another irrigation line to the worst ‘yellow’ areas or reducing micro-sprinkler output in the vigorous ‘blue’ areas and to even-up vigour.

A rule of thumb in broad-acre agriculture is that within block variation has to exceed 15% to justify taking action. That’s probably a conservative starting point for horticulture where there is a lot of money left on the table if we have underperforming areas. Variation is closer to 50% in this example. Repeat scans over the following seasons will show how well the chosen action is working.

Summing up

The evolution of pruning styles discussed at the start of this article evolved over decades. The rapid development of scanning technology is bringing some great canopy and crop management tools within years.

When discussing growing systems and ultimate yield potential, Richard Hill of Mr Apple makes a good point – “we haven’t got there yet”. I agree and reckon that ‘getting there’ won’t just be about which growing system proves to be the best but how well we can identify under performance within blocks and actually fix it.

Disclosure : Fruition Horticulture (Hawke’s Bay) Ltd, Green Atlas and Applied Research Technologies are collaborating to introduce scanning services to horticulture in New Zealand.

Images and data obtained from Green Atlas Cartographer operated by Fruition.